Workshop: Risiken in der tieferen Lieferkette adressieren

Workshop: Risiken in der tieferen Lieferkette adressieren

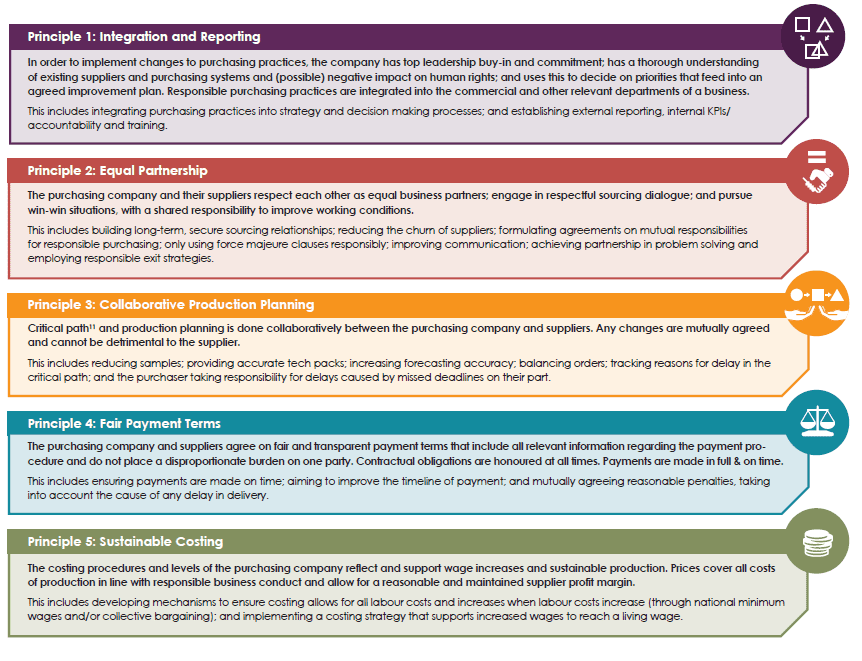

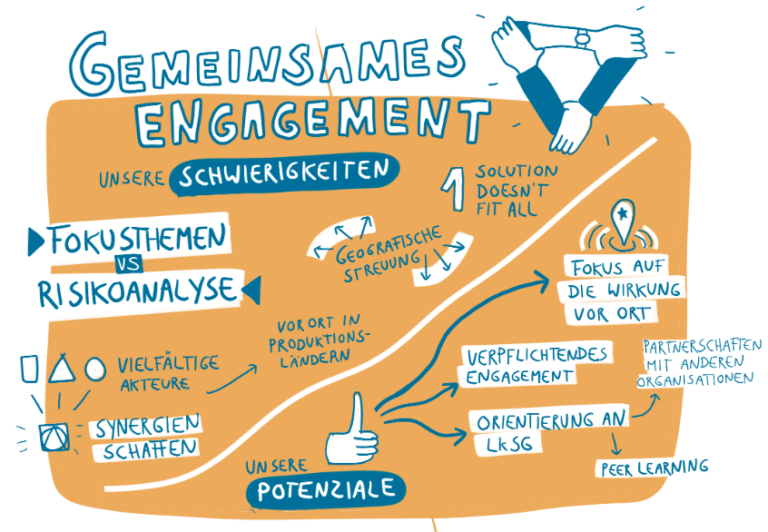

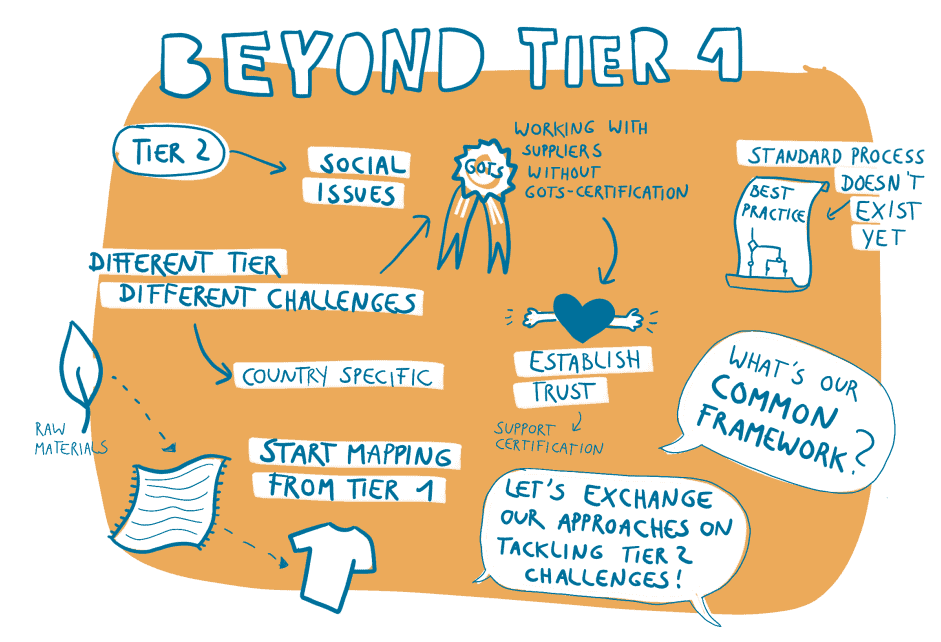

Für Unternehmen ist es wichtig, die sozialen und ökologischen Risiken in ihrer Lieferkette zu analysieren und zu priorisieren. Bislang beschränkt sich die Risikoanalyse jedoch häufig nur auf direkte Zulieferer (Tier 1) und dringt nicht bis in tiefere Stufen der Lieferkette vor.

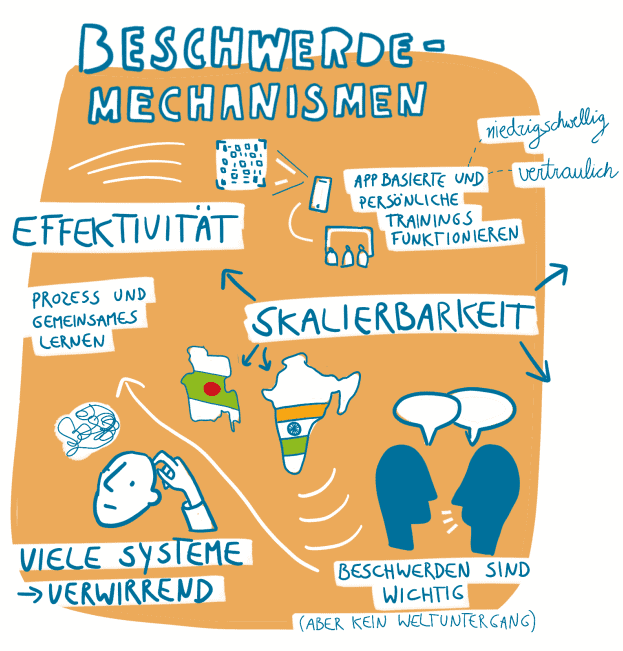

Ziel des Workshops „Beyond tier 1 – due diligence risks in the deeper supply chains” war es deshalb, Herausforderungen und Lösungsansätze zu diskutieren, wie Unternehmen Risiken gezielter und systematischer erfassen und so auch in der tieferen Lieferkette ihrer Sorgfaltspflicht besser nachkommen können.

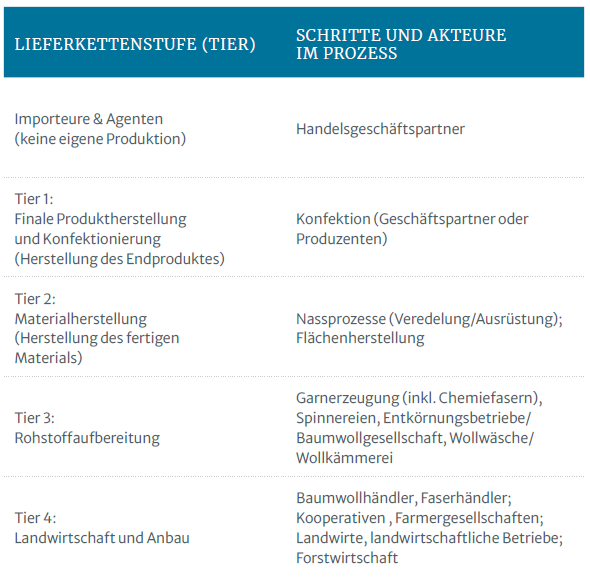

Die Risiken können sich je nach Stufe der Lieferkette oder Produktionsland unterscheiden:

Quelle: Textilbündnis-Handreichung: Schritt für Schritt durch den Review-Prozess.

Zu Beginn des Workshops gab Silvia Mera Einblicke in ihrer Arbeit bei von GoodWeave International und wie sie dort, mit Zulieferbetrieben zusammenarbeiten und die Arbeitsbedingungen in den Betrieben überprüfen. Laut Mera sind zwei Aspekte besonders wichtig:

- Effektive Standards (z. B. Verhaltenskodex), die sich auf alle Ebenen der Lieferkette beziehen,

- Inspektionen und Überwachung (z. B. unangekündigte schnelle Fabrikaudits) Abhilfe und Vorbeugung (z. B. Bewusstseinsbildung, bei Heimarbeitern auch auf Ebene der Familie)

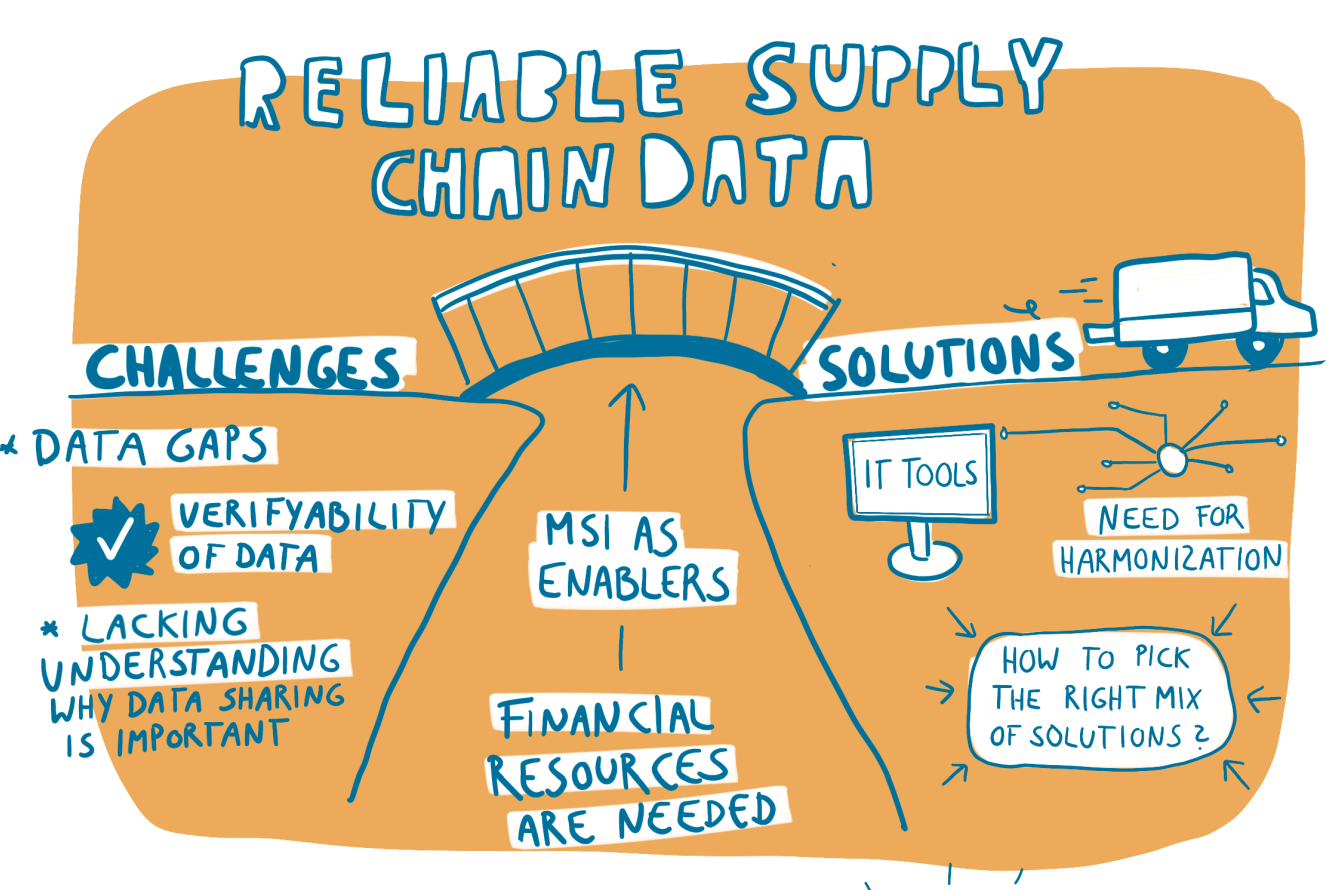

Risiken zu ermitteln, gestaltet sich vor allem dann schwierig, wenn Unternehmen keinen direkten Kontakt zu ihren Lieferanten haben oder ihre tiefere Lieferkette nicht kennen. Die Komplexität und Vielzahl an Akteuren erschweren den Austausch über soziale und ökologische Risiken. Diese Distanz lässt sich nicht mit einseitiger Kontrolle seitens der Unternehmen verringern, sondern erfordert den langfristigen Aufbau vertrauensbasierter Beziehungen in der tieferen Lieferkette.

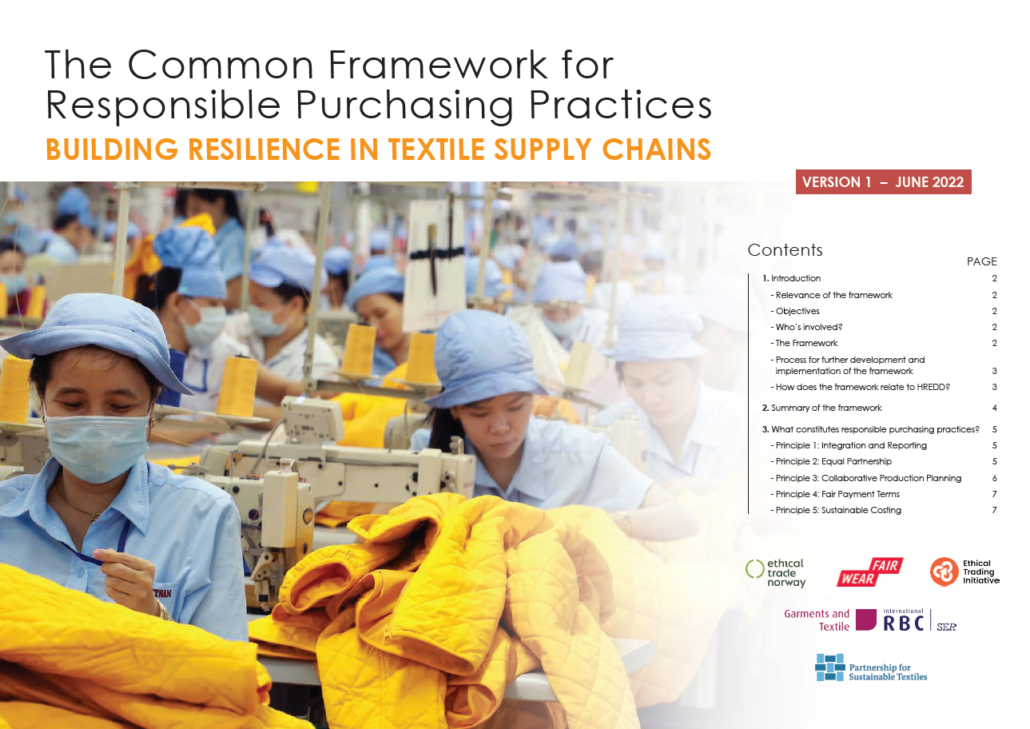

Einheitliche Standards und Instrumente können helfen, Akteure in der tieferen Lieferkette zu motivieren, Risiken gemeinsam mit Geschäftspartnern zu adressieren und auf Missstände aufmerksam zu machen. Gleichwohl fehlten bislang einheitliche Standards, an denen Unternehmen sich orientieren können. Im Higg Facility Social & Labor Module (FSLM) sahen die Teilnehmenden ein geeignetes Tool, das produzierende Unternehmen anhand von neun sozialen Kategorien unterstützt, die Arbeitsbedingungen in ihrem Betrieb zu analysieren und zu verbessern.

An Ende des Workshops stand dieses Fazit: Derzeit gibt es keine umfassenden Standards oder Empfehlungen, um sozialen und ökologischen Risiken in der gesamten Lieferkette systematisch anzugehen. Für Marken bedeutet dies, dass sie viel Zeit und Mühe aufwenden müssen, um mit ihren mit ihren Tier-2-Lieferanten in Kontakt zu treten und vertrauensvolle Beziehungen aufzubauen, um die Arbeitsbedingungen zu verbessern.

Eine individuelle Risikoanalyse anhand von elf sozialen, ökologischen und Korruptions-Risiken (Sector Risks) ist daher Grundlage der Berichterstattung im Textilbündnis (Review-Prozess). Basierend auf den Ergebnissen der Risikoanalyse und Risiko-Priorisierung leiten die Unternehmen Ziele und Maßnahmen ab, um potenziellen Risiken vorzubeugen und tatsächliche negative Auswirkungen abzumildern.

Weitere Infos zum Review-Prozess: Der Review-Prozess – Bündnis für nachhaltige Textilien (textilbuendnis.com)