10th Members' Meeting

10th Members' Meeting

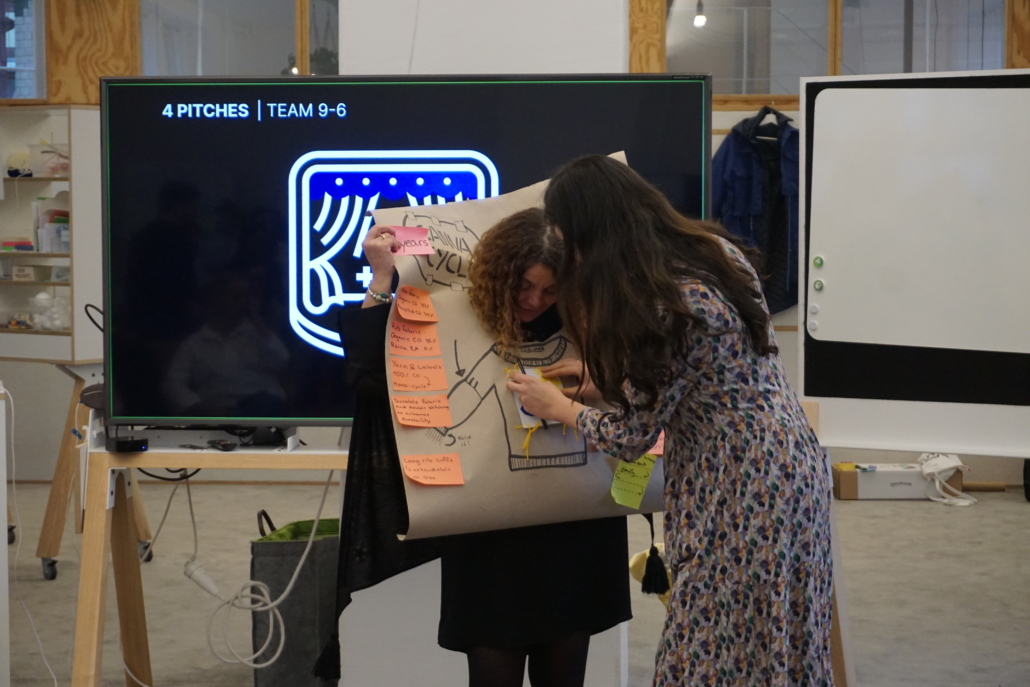

Around 125 participants attended the 10th Members’ Meeting of the Partnership for Sustainable Textiles in Berlin. They engaged in lively discussions in presentations, workshops and working groups and laid further important groundwork for the implementation of the strategic reorientation. One highlight was the exchange with representatives of rights holders from Bangladesh.

Head of the Textiles Partnership Linda Schraml opened the meeting with a look at the importance of the strategic realignment:

"The world has moved on since the Textiles Partnership was founded almost ten years ago. This has also brought about changes in the regulatory environment. In order to take these changes into account, we decided on a strategic reorientation at the end of 2022 and began implementing it in 2023. New requirements were placed on partnership members, e.g. for greater transparency in the supply chain. The implementation of the focus topics along the supply chain is becoming increasingly important. We are particularly proud of the ten of the current eleven Partnership Initiatives that were developed in 2023 and in which the members are actively involved in a wide range of topics."

In einer Q&A-Session mit dem neuen Steuerungskreis – vertreten durch Claudia Kersten, Berndt Hinzmann, Anna Ruechardt, sowie Anja Hanslik, Luise Scheuber und Moritz Blanke und in den anschließenden Austauschrunden ginge es u.a. um die Key Performance Indikatoren, die Gesetzgebungen und ein Stimmungsbild innerhalb der Akteursgruppen.

Achieving more together on the ground

Dr Bärbel Kofler, Parliamentary State Secretary at the German Federal Ministry for Economic Cooperation and Development (BMZ), highlighted the Textiles Partnership as a pioneer compared to other industries and as a trailblazer for legal guidelines in her speech:

"In the past, the textile industry was often seen as a problem child. Today, however, it is in many cases a role model for other sectors. Even before the law, they showed how compliance and corporate due diligence work in practice. They implemented years ago what the German Supply Chain Act now requires. We will probably soon also have a European supply chain law. That is a great success.

In this regard, Kofler emphasized the need for the EU supply chain law and the importance of the multi-stakeholder nature of the alliance:

As the largest common market in the world, the EU needs uniform rules to ban human rights violations from supply chains." [...] In this respect, the EU Supply Chain Act offers companies important support in fulfilling the legal requirements. For example, by promoting joint risk analysis and remedial action by partnership members. The European directive will therefore further strengthen the role of multi-stakeholder partnerships. Because only if we build on partnerships based on respect and reciprocity will we achieve a sustainable and socially just textile industry.

The State Secretary emphasized how important it is to build on local structures in the production countries and to involve rights holders even more strongly and systematically in the Partnership’s work.

Talking to and not about Rightsholders

Taking up Kofler's appeal, the members listened intently to the exchange with the two rights holders Tithi Afrin, program coordinator at the National Garment Workers Federation (NGWF) and Shahinur Rahman, consultant for FEMNET, GoodWeave International and Mondiaal FNV.

As programme coordinator of a workers' rights organization in Bangladesh, Tithi Afrin emphasized the importance of better working conditions, the payment of living wages and freedom of association. In this context, she presented the EIS (Employment Injury Scheme) program in Bangladesh. This forms a financial safety net for textile workers in Bangladesh in the event of a work injury. Afrin hopes that the EIS will be sustained for a long time and will be accessible to all textile workers in the future.

Rahman tried to raise awareness of the considerable differences in the power relations between the textile workers and their factories, but also between the suppliers and the brands. In this context, he appealed to the brands to use their position to advocate more strongly for rights holders vis-à-vis and within industry associations.

Both emphasized the need for legitimate and genuine trade unions and direct contact with their representatives. Afrin and Rahman appealed to the members that the brands must proactively approach workers' representatives and check their legitimacy in order to get an authentic picture of the working situation and to have the interests and wishes of textile workers in the production facilities included.

The afternoon of the second day was therefore dedicated to in-depth, joint work on the four focus topics, the Bangladesh EIS and the empowerment of rights holders in various round tables and workshops.