Workshop: Using data to achieve more transparency in supply chains

Workshop: Using data to achieve more transparency in supply chains

In order to be able to ensure corporate due diligence, it is necessary to know one's own supply chain as precisely as possible and to establish transparency. Companies should know which actors are involved in the production of their products, where they are produced and under what circumstances. Only with this knowledge can they identify and address social and environmental risks. The complexity and diversity of suppliers in textile supply chains has so far made it difficult to reliably collect the necessary data.

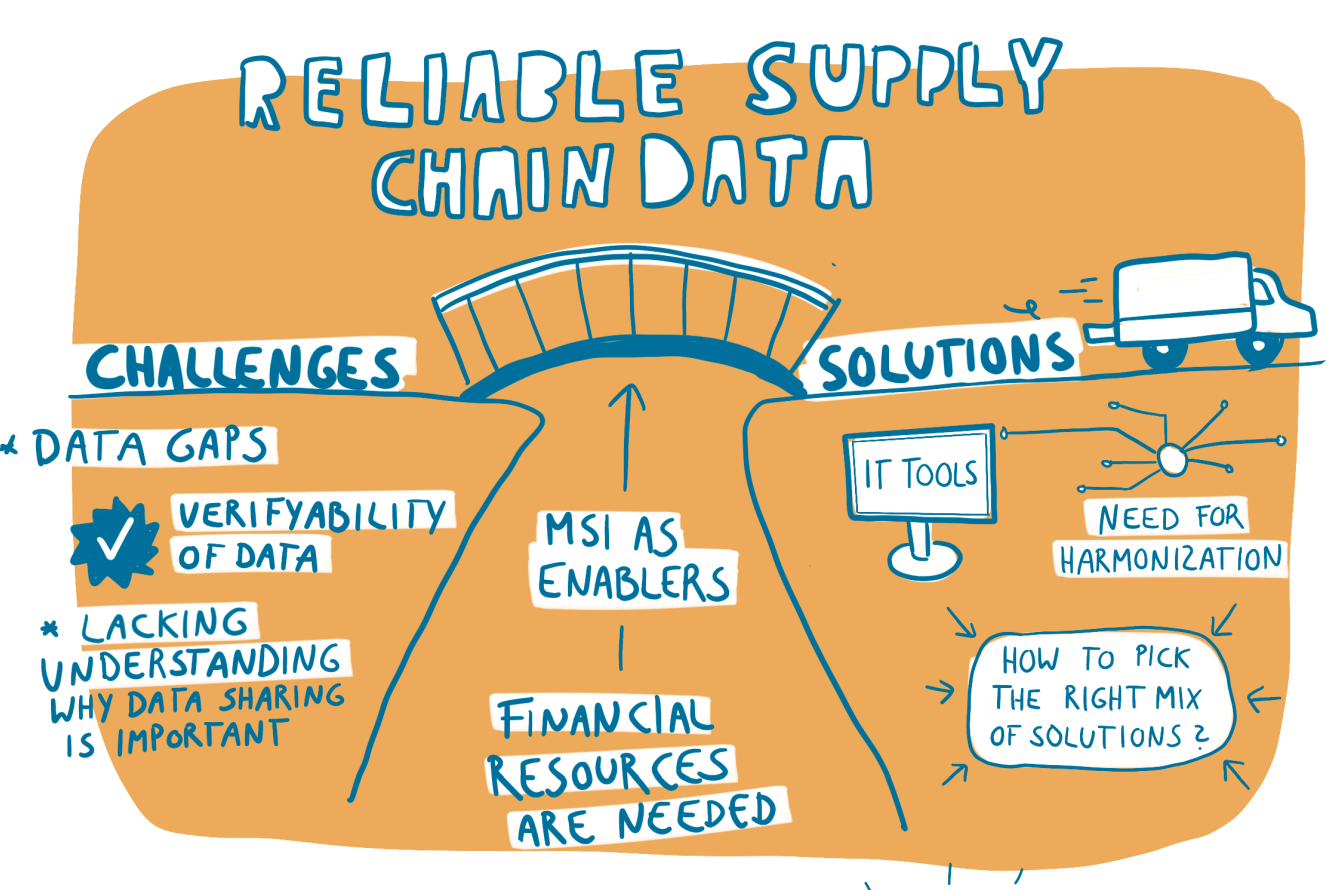

The aim of the workshop "Reliable Supply Chain Data for the Implementation of Human Rights and Environmental Due Diligence" was therefore to discuss challenges and possible solutions on how to collect data more efficiently and systematically and how to better map textile supply chains.

Obtaining reliable data from the supply chain and creating transparency becomes more difficult the deeper companies go into the supply chain - for example, in the sourcing of cotton. Often companies have no direct contact or do not know their deeper supply chain. The multiplicity of suppliers and complexity of the supply chain also complicate data exchange as well as verification and quality assurance. In addition, there are many different methods and requirements with varying focus, but hardly any uniform standards for the collection and management of data.

Digital tools can help to collect data in a systematic way and fill data gaps, for example with databases, platforms and tools such as Open Apparel Registry or HIGG. They should also be used for deeper supply chain levels. There is also potential in blockchain technology. However, the alliance members in the workshop also stressed that certain data protection requirements must be guaranteed in all of this.

Many suppliers are reluctant to share data, often for fear of negative consequences. In addition, not all actors in the supply chain are aware of the benefits of reliable data. Therefore, many Partnership members emphasised that, on the one hand, continuous dialogue and mutual trust are important to address the issue with suppliers and thus create more trust. On the other hand, financial investments are also needed to build up the necessary capacities and systems.

Multi-stakeholder initiatives such as the Textile Partnership can provide support, raise awareness and promote the harmonisation of data. The Textile Partnership has an expert group on supply chain transparency and cooperates with the Open Apparel Registry (OAR). In the course of this, the Textile Partnership has published an aggregated list with a total of around 6,850 production sites of 23 member companies via the OAR.

The workshop was part of this year's Textile Partnership working meeting on 17 and 18 May in Berlin. The unconference format gave Partnership members the opportunity to propose their own topics and questions that they would like to work on together.