Environmental protection & use of resources

Each stage of the textile supply chain has an impact on the environment. Due to the wide range of processes, raw materials and finished products, the impacts can vary greatly in nature and scale. The greatest risks lie in the production and processing of raw materials.

As early as the manufacturing of the fibres, it is important to use environmentally friendly and sustainable processes. An example is cotton, which makes up the largest share of natural fibres. Cotton farmers can contribute in various ways to conserving soil and water and preserving biodiversity. For example, they can reduce the use of synthetic pesticides or abstain from using them altogether. If they choose modern cultivation methods or switch to growing organic cotton, the negative environmental impacts are significantly reduced. In addition, farmers can achieve higher prices and benefit from long-term trade relationships, making further investments in sustainable cotton production worthwhile. For man-made fibres, the share of recycled or bio-based fibres could be increased.

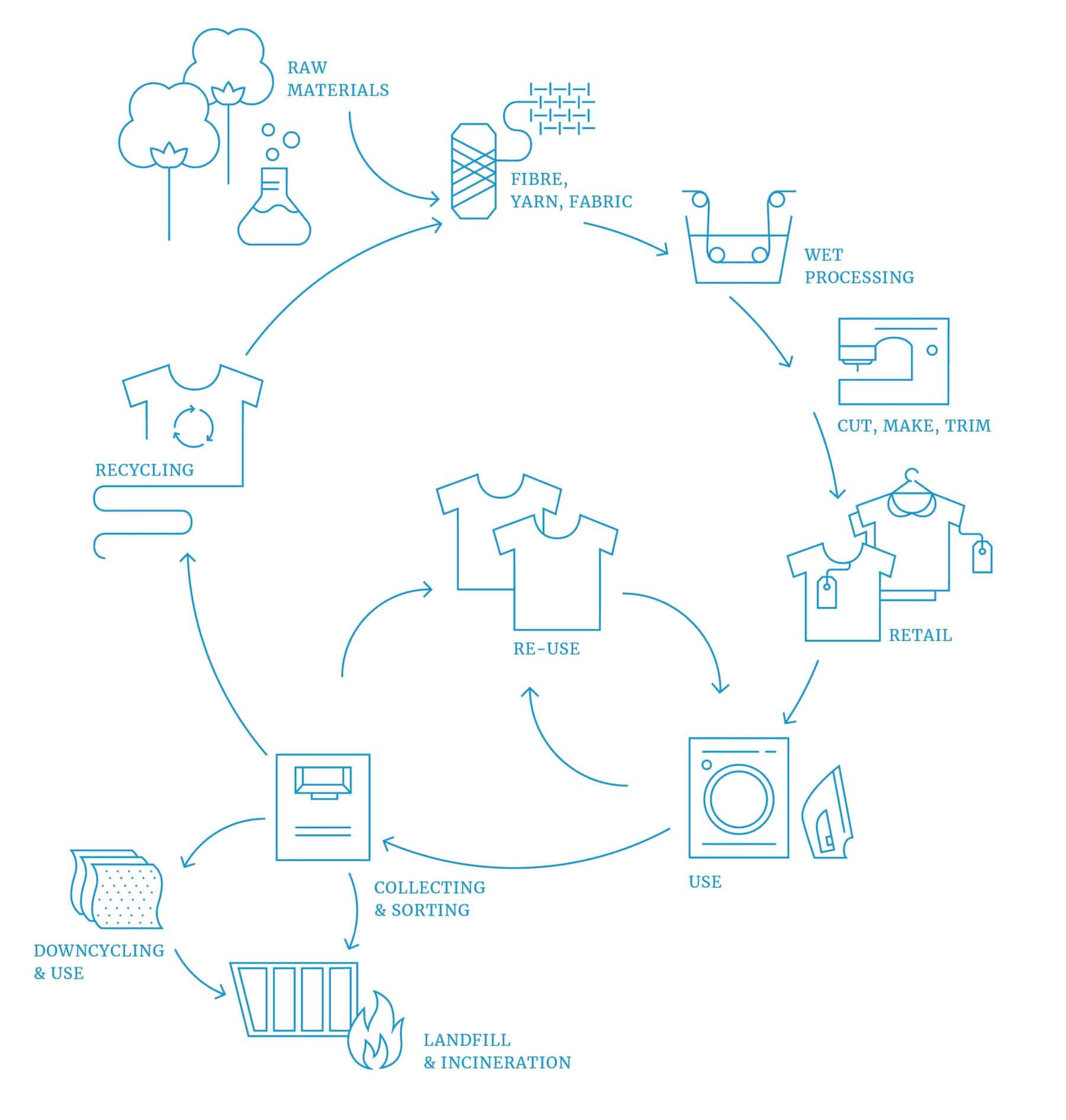

Besides the negative environmental impacts, the consumption of resources and land in the textile sector is also very high. Therefore, the concept of the circular economy is becoming more and more important. The aim is to preserve the value of textiles for as long as possible and to regard "waste" as a valuable raw material. Waste and resource consumption should be kept to a minimum and the resources used should be returned to the economic cycle. Recyclable fibres and the reuse of textiles - for example through second-hand and new business models such as sharing and renting platforms - are just two of many approaches. A circular textile economy respects planetary boundaries and protects natural resources sustainably.

The sector risk of environmental protection is closely related to the Sector Risk of chemical use and wastewater , because many chemicals are used, especially in textile wet processes, which can sometimes be dangerous for people and the environment. However, production companies often lack awareness of the problem. As a result, chemicals are stored and used in an unsafe manner, workers are not adequately protected and contaminated water is not treated properly.

The Textiles Partnership has set out to significantly improve working and environmental conditions in the value chains of the textile and garment sector. In order to protect the environment and conserve resources, the Textiles Partnership takes action in several areas, including fibres, circular economy and climate protection. Sector risk of chemical use and wastewater are a separate sector risk.

Sustainable natural fibres

All members of the Textiles Partnership have the common goal of increasing the share of sustainable cotton to 70 percent by 2025; organic cotton should account for at least 20 percent of this. In the Review Process , the Partnership companies provide information on the fibres they use and their sustainability. They can provide evidence of this, for example, through standards and seals.

During the Pilot Project Organic Cotton in India (South Odisha) several companies and organisations have joined forces with the aim of increasing the amount of available organic cotton on the world market.

In addition, the Textiles Partnership is planning a Partnership Initiative on organic cotton. Brands, retailers and standard setting organisations can participate. If you would like to join or learn more, please contact us: mail@textilbündnis.com (Sarah Kurz).

Although virgin wool only accounts for a comparatively small share of the total fibre quantities, it is second only to cotton among natural fibres in terms of volume. Animal welfare is the most important factor in the production of virgin wool. This too is a sector risk. More information can be found here.

Expert Group Circular Economy

In 2020, the Expert Group (EG) on Circular Economy was launched, in which almost 40 Partnership members participate. They primarily focus on sustainable design and its impact on the recyclability of textile products. In addition, the EG is dedicated to the durability and recyclability of textiles as well as the question of varietal purity and the use of recycled fibres. Best practices and guidelines are used and implemented through cooperation with experts in the field of recycling.

In March 2021, the working group on recycling launched a project "Recyclable Product Clones"In the project, eleven selected products from the members are been examined by the Research Institute for Textiles and Clothing at the Niederrhein University of Applied Sciences in terms of their recyclability. The selection includes a backpack, PES-based functional laminates, bed linen, women's clothing, socks, work wear and hiking shorts.

"How to create a sustainable and inclusive collection & sorting system?" This question is also discussed by the members of the EG Circular Economy and appropriate solutions are developed. And last but not least, the EG deals with alternative business models and sustainable packaging made of recyclable materials. Among other things, the EG has compiled a glossary in circular economy.

Cooperation

Some of the strategic cooperations of the Textiles Partnership with other organisations focus on environmental protection, the promotion of sustainable fibres and the use of chemicals, for example the cooperations with SAICM, Textile Exchange, Organic Cotton Accelerator and ZDHC.

Further information and tools:

Adelphi / GIZ: Circular Economy in the Textile Sector (2019).

Textile Exchange: Organic Cotton Market Report (2021).

Partnership for Sustainable Textiles: Circular Economy Glossary (2021).

CottonUP: A practical guide to sourcing more sustainable cotton.

Helpful links on the subject of virgin wool:

International Wool Textile Organisation: IWTO Specifications for Wool Sheep Welfare (2020).

Textile Exchange: Responsible Wool Standard.