Annual Report 2023

Annual Report 2023

At the 10th members' meeting on 17 and 18 April, Linda Schraml, Head of the Partnership Secretariat, presented the 2023 annual report to the members. It shows that the Partnership for Sustainable Textiles was able to realise its realignment in 2023 despite the high demands placed on it:

- Nine new members have joined the Textiles Partnership

- Ten of the current eleven partnership initiatives have been developed

- The steering committee was newly elected

- The Partnership Initiative (PI) 'Living Wage Lab' is now entering its second phase in order to strengthen the rights of workers in supplier factories in Bangladesh, India and Pakistan

- The Partnership Initiative (PI) 'Advancing Worker-led Agreements on Gender Justice', for example, supports the Dindigul Agreement by extending the agreement to other suppliers in the Indian region of Tamil Nadu

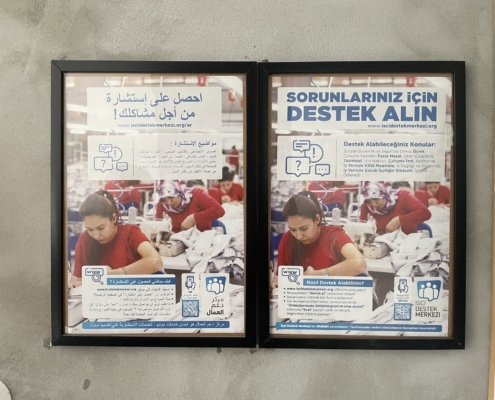

- The project 'Strengthening factory grievance mechanisms in Pakistan' was successfully completed with a total of 25,500 workers participating in training courses on factory grievance mechanisms

In her greeting, Federal Minister for Economic Cooperation and Development Svenja Schulze emphasised that trust and strong partnerships are needed to overcome the crises and challenges of our time: „You, the members of the Partnership for Sustainable Textiles, are leading by example. In refocusing the Partnership and putting even more emphasis on Joint Action you are taking an important step in the right direction. And in taking this step, you are doing what the Due Diligence Act requires. After all, the core element of this Act is not the reporting. It is more about taking targeted action in order to address shortcomings along the supply chain. By working together, you can achieve more than by going it alone. And you are able to deliver measurable social and ecological improvements along the textile supply chain.'

In addition, Chapter 4 provides updates on the four focus topics and the Partnership Initiatives on which the Partnership members are working together:

- Living Wages and Purchasing Practices

- Circular economy and climate protection

- Gender equality

- Grievance mechanisms and remedy

In 2023, all Partnership companies submitted at least their Tier 1 supplier data to the Partnership Secretariat for the first time. You can find out exactly how this worked and which data is particularly worth knowing in chapter 5.